The Key to Improving Capacity Is Improving Effectiveness

Buying a new die casting machine and the personnel to operate it is the single most expensive way to increase capacity. Instead make your existing machines 10, 20, or even 30% more efficient for a fraction of the cost.

OEE, “Overall Equipment Effectiveness”, is a percentage indicator which represents the global performance of a production resource or set of resources, whether human or technical, during the time in which these are available to produce.

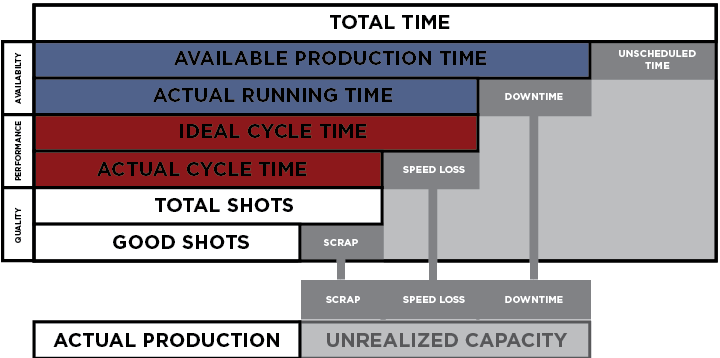

OEE (Overall Equipment Effectiveness) Capacity Diagram for Die Casting – actual production is a measure of total capacity minus capacity lost to maintenance, downtime, speed loss, and scrap.

We’ve spent the last 40 years helping our customers build more effective operations. Every part of our product line can help you increase capacity; allowing you to delay or avoid huge capital expenses.

Small increases in OEE can dramatically improve margins, and can quickly add up to the capacity of a new shot system.

- Increasing run time per shift by decreasing part set-up time,

- Reducing avoidable maintenance and downtime by reducing flash

- Utilizing the the full capacity of and capabilities of your shot system.

- Increasing shippable shots per hour by reducing defects.

You are already sitting on a gold mine of unrecognized revenue potential, believing you are at the end of your production capacity.

PRODUCTION REPORTING:

Get the insight you need to see where effectiveness is dropping and why. (more)

SHOT MONITORING:

Understand the complex dynamics of every shot and the underlying causes of scap, speed reduction, downtime and more. (more)

SHOT CONTROL:

Control every aspect of the highly dynamic shot event with pinpoint precision. Avoid costly flash, scrap, and downtime increasing your shippable shots per hour. (more)

Comments are closed