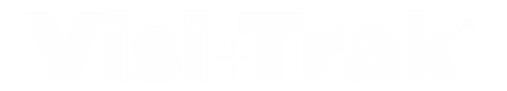

FT2/L™ High Speed Data Acquisition

The basic building block

The FT2/L™ is an engineered High Speed Data Acquisition System for gathering high speed process data from the shot-end of a die casting machine.

Highly configurable

The shot end of the machine must be fitted with the appropriate sensors for measuring position/velocity of the shot cylinder and pressures in the hydraulic system. Various other types of analog sensors can be connected and monitored by FT2/L™

Modular Design – Easily Upgradeable

Monitor real-time DCM status in back office or plant via Ethernet. This first building block can easily be upgraded from DCM monitoring system to real-time control system.

Highly Compatible

Compatible with all major machines. Capture position, velocity, and more. 16 analog input channels; 8 single point input channels.

alarm Capability

Alarm output capability for up to 8 programmable limit switches or alarm condition process control parameters.

Easy Connectivity

Connects to TRUE-TRAK 20/20™ DCT via category 5 Ethernet cable. Spare external RJ 45 connector port for attachment of PC.

Upgrade to a complete system.

This modular design can easily be upgraded to a fully integrated True-Trak 20/20 Computer Monitoring System with CPU, Touchscreen LCD Display, keyboard & mouse, and more to view the shot traces right at the machine.

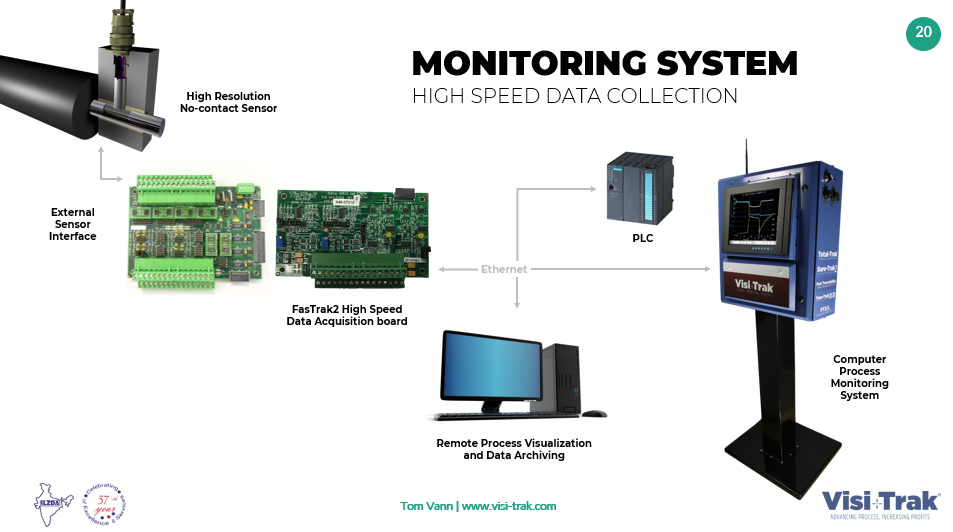

True-Trak 20/20™ DCT

For an FT2/L system, you need to use either a True-Trak 20/20 Data Collection Terminal (DCT) or you need to load the True-Trak 20/20 software on a shop office PC. Up to eight FT2/L’s can be monitored per DCT or shop office PC. For a ninth FT2/L, simply add a second DCT or shop office PC.

Built to Last

An industrially hardened system designed specifically for the shop floor. It can withstand hot, dirty environments for many years of reliable performance.

Parameter Analysis

Measure Position, Velocity, Pressure, Temperature, Flow, Time, Die Surface Temperature to optimize throughput and minimize variation.

Sample Configurations

Examples of different FT2/L system configurations.

Configuration One

Data Collection Terminal

Configuration Two

Remote Data Collection

Configurtaion Three

Fully Integrated PC Monitoring System