When speaking with Zinc die casters, we often hear that we can’t help them because of the sheer speed of the hot chamber cycles or the short distance traveled by the plunger tip.

Here, we’ll provide some clarity about response time, hydraulic design, and what we offer.

Myth #1: Hot chamber doesn’t need monitoring; we’ll just catch the bad parts later and remelt them.

Every casting that is produced and not sold is lost revenue. Every casting returned to you by your customer is far worse. Hot chamber casting quality is the combination of critical factors like peak fast shot consistency and precise piston travel distance.

- Process variation creates quality variation, and you are losing bins of valuable parts and weeks of production capacity to these addressable issues.

- Visi-Trak can alert you to the root cause of non-fill, cold flow, knit lines, blistering, porosity, and mass variation as they happen instead of downstream where more value-added time is lost.

Some miscasts are less obvious than others.

A bad part is, at best, additional cost and, at worst, a lost customer.

Myth #2: Valve response is too slow to control hot chamber machine shots.

If Response Time of the cartridge valve is 5 ms, and my fill time is 20 msec, how applicable is closed loop control over this short amount of time?

Consider that Response Time is often measured full close to full open. Whereas in practice, our command is matched to the valve and can precisely control velocity changes incrementally as the cylinder advances. This affords you the capability for the most precise and repeatable performance of your shot.

Myth #3: The stroke distance of the hot chamber die casting is too short to measure, or too short to need monitoring.

Unless you’re making 100% good parts, there is variation in your process, no matter how short the stroke distance is.

- Does the plunger accelerate identically to the exact same speed every time?

- If you could overlay 100 cycles of production shot data, would you see one shot trace or many?

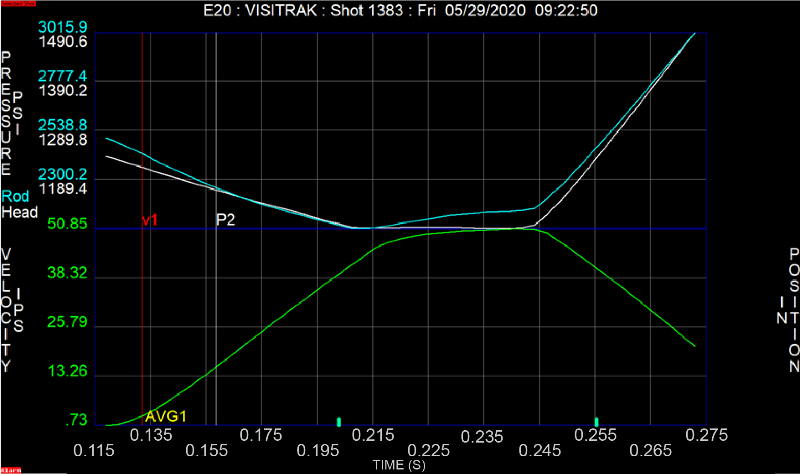

Visi-Trak captures data every 0.0125” of plunger travel, more than enough to capture the variation and identify the machine problem and the scrap.

Hundreds of velocity, pressure, and position data points captured in even the rapid, short-stroke hot chamber shots.

Overlay shot after shot to discover changing process conditions, discover the cause of variation, and stop bad parts before they are made.

Myth #4: Our cycle times are too fast for your monitoring system.

There are certainly zinc die casters creating small parts with incredibly short cycles times. A good rule of thumb is that if your complete cycle time is at least 1.25 seconds, we can offer better insights, increased performance, and synchronize your entire machine cell.

We’re ready to show you how Visi-Trak can help even the most robust zinc operations achieve peak performance.

Comments are closed