Smart phones. Smart TV’s. Smart cars. Smart homes. Smart factories. Smart die casting. Foundry 4.0.

What is Foundry 4.0?

In recent years, Foundry 4.0 has been one of the buzzwords you may have heard when discussing the topic of manufacturing. Specifically die casting. Foundry 4.0 involves an increase in automation in an effort to reduce defects.

The basic principle of Foundry 4.0 is that by connecting machines, work pieces, and systems, businesses are creating intelligent networks along the entire value chain that can control each other autonomously. Automation is improved by the introduction of self-optimization, self-configuration, self-diagnosis, cognition, and intelligent support of workers in their increasingly complex work.

Foundry 4.0 reduces the human element because autonomous systems use big data (another term you may have heard in recent years) to make sure machines are functioning properly. These same systems can take corrective action if they determine the machines are not functioning properly. Pretty cool idea, right?

Why is Foundry 4.0 Important?

In today’s fast-paced world, manufacturers are under pressure to get the job done and to get it done right. The die casting industry is a high-stakes industry. If defects in production occur, companies have a lot to lose. Defects can lead to liability issues and brand name issues, not to mention a huge loss in profits, and potentially a loss in customers.

Foundry 4.0 is important because it allows die casters to execute the die casting process in a smarter way. It involves the use of software programs that can monitor the die cast process and provide data about each step in the process. This software then can analyze the data and make decisions to resolve any thing it determines is an error in the process. Thus, the use of automation reduces those problematic defects. The outcome is a more efficient process.

Visi-Trak Meets Foundry 4.0

Foundry 4.0 involves the usage of PLC and automation, sensors, continuous monitoring, process data analysis, production data collection, process and administration, interconnection, quality control, and closed loop control.

These concepts and processes are not new to Visi-Trak. While others in the industry are calling it “Foundry 4.0”, we simply call it Visi-Trak. Why? Because we have been doing this all along. Our business has always been based on Foundry 4.0, long before the term even existed.

For over 40 years, we have provided our customers with services and products to help them with the following:

- Analyze data across machines

- Real-time decision making based on analytics

- Using simulations to test machine settings

- Shorten machine setup times

- Process automation

- Use of sensors

- Combination of position and time based sampling (provides more data than time-based alone!)

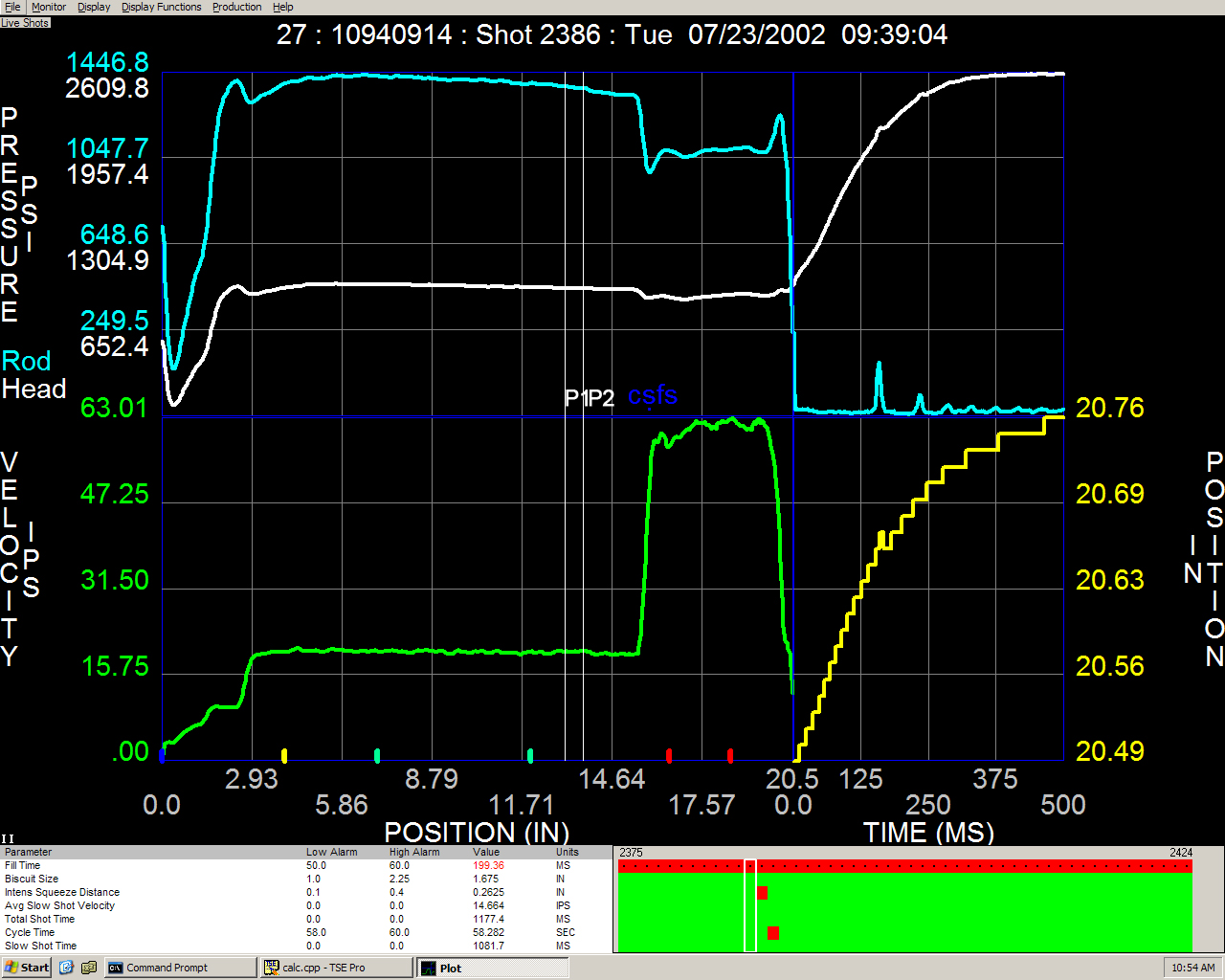

With a Visi-Trak system, you can monitor positions, velocities, pressures, temperatures, flows, and times. You can also process analysis through statistics such as parameter trends, Cp/CpK capability, correlation, and X-R charts. On top of all this, our systems provide production data including OEE, downtime tracking, and cycle timers.

How Visi-Trak’s Foundry 4.0 Benefits You

- Optimize every shot reducing part variability

- Orchestrate the entire machine cell via PLC control so that each system is aware of the other systems

- Provides remote access, view, and control of every aspect of your production

- Predict and avoid failures by triggering maintenance to react to unexpected changes in production

- Data from post-processes in the same record for perfect traceability and quick access

- A single networked view of your entire organization with smart alerts and business insight

Better Decisions, Better Parts, Better Margins

We help our customers make better decisions, better parts, and better margins. Through the use of key operational insights, our customers can make better decisions. These operational insights allow you to understand the causes of downtime, optimize equipment utilization, and see what is actually happening on the shop floor. Our customers are able to make better parts because they are preventing defects such as trapped gases, material separation, shrinkage, porosity, blistering, cracks and leaks, and other defects. Margins are better because production costs are lowered – our customers can increase their bottom line, make more shippable parts per hour, reduce scrap, increase OEE, and produce higher margin parts.

Production Data Where and When You Need It

- Report crucial data directly to decision makers for real-time continuous improvement

- Identify the causes of waste that are costing you money

- Automatically export data directly to your SQL Database

- Easy access of data for SPC Analysis, Trending, Management Decisions, and more

- Minimize the time spent on Process Development and Optimization

Foundry 4.0 is here. Smart die casting is here. Are you ready?

Comments are closed